In a groundbreaking effort to tackle the pervasive issue of microplastic pollution stemming from clothing, scientists from the U.S. Department of Energy’s (DOE) Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE™) consortium have pioneered a promising solution. The rampant shedding of polyester fibers, often invisible to the naked eye, has contributed significantly to environmental degradation and public health concerns.

The advent of a non-toxic, biodegradable alternative to petroleum-derived polyester marks a significant stride in combating this escalating problem. Known as PHAs, or “polyhydroxyalkanoates,” these innovative materials offer a sustainable substitute that addresses the issue at its source.

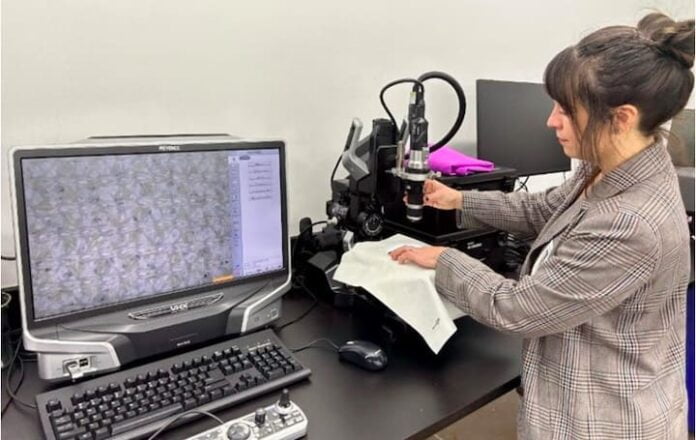

Driven by the DOE Bioenergy Technologies Office (BETO) and Advanced Materials & Manufacturing Technologies Office, the BOTTLE consortium, comprising experts from the National Renewable Energy Laboratory and Colorado State University, has successfully developed a range of PHAs in laboratory settings. These PHAs boast diverse properties, mimicking conventional polyester while being bio-based, biodegradable, and more readily recyclable.

The collaborative efforts of BOTTLE and renowned outdoor apparel brand The North Face herald a significant step towards integrating sustainable materials into mainstream consumer products. Over the ensuing 12 months, BOTTLE aims to scale up the production process, generating several pounds of PHA fiber for rigorous testing and evaluation by The North Face.

The partnership between BOTTLE and The North Face underscores a shared commitment to driving innovation and sustainability within the textile industry. By leveraging cutting-edge research and fostering industry collaborations, the initiative endeavors to revolutionize textile production and mitigate the adverse environmental impacts associated with conventional polyester.

This groundbreaking endeavor holds promise not only for reducing microplastic pollution but also for fostering a more sustainable and environmentally conscious approach to textile manufacturing. As efforts continue to advance, the prospect of widespread adoption of PHAs in clothing production represents a significant milestone in the journey towards a greener, more sustainable future.